Product Description

Waterproof, moisture-proof, anti-corrosion, anti-mold, anti-worm moths, non-deformation wood plastic products have the dual characteristics of wood and plastic, so wood plastic set door in addition to the use of indoor room door, especially suitable temperature difference, humid, poor ventilation of places, such as damp toilets, need to prevent corrosion, mold, moth-proof storage room. Reasonable structure, high strength special cavity structure design, to ensure the ideal internal structure of wood-plastic foaming material, coupled with excellent formulation design and reasonable production process, to ensure the strength of the product. Fast installation structure, installation of time-saving wood plastic door using the German introduction of fast-loading structure, door cover installation is extremely convenient, door cover wire and door cover with a mount connection, no need for nails or adhesive fixed.

This new generation of fast-growing wood plastic composites (WPC) offers excellent mechanical properties, high dimensional stability, and can be used to form complex shapes. Wood plastic composites have found tremendous application space for non-structural outdoor residential decoration, and are also being used in other housing building materials, such as flooring, door and window decorative parts, corridors, roofs, automotive decoration materials, and various equipment for outdoor gardens and parks.

WPC floor wear layer has a special non-slip, and compared with ordinary ground materials, WPC floor in the case of water-stained feet feel more astringent, less likely to fall, that is, the more water more astringent. Therefore, in public places with high public safety requirements, such as airports, hospitals, kindergartens, schools, etc. are the preferred ground decoration materials. It has become very popular in China in recent years.

Feature Details

Structural Profile

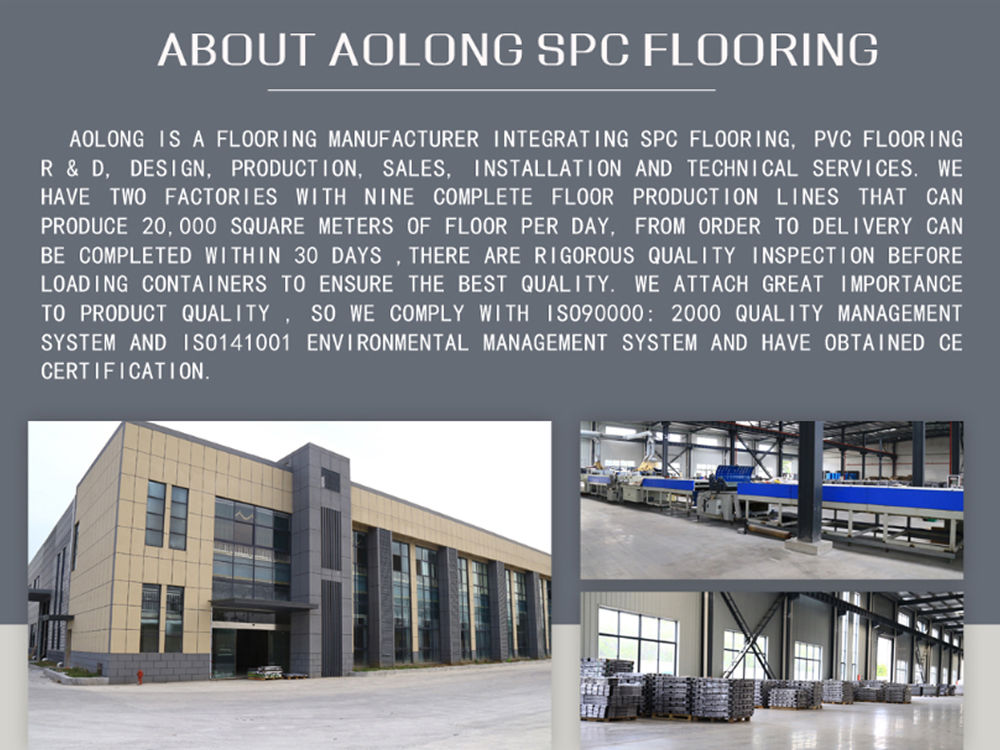

Company Profile

Test Report

Parameter Table

| Specification | |

| Surface Texture | Wood Texture |

| Overall Thickness | 8mm |

| Underlay(Optional) | EVA/IXPE(1.5mm/2mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Size specification | 1200 * 180 * 8mm |

| Technical data of spc flooring | |

| Dimentional stability/ EN ISO 23992 | Passed |

| Abrasion resistance/ EN 660-2 | Passed |

| Slip resistance/ DIN 51130 | Passed |

| Heat resistance/ EN 425 | Passed |

| Static load/ EN ISO 24343 | Passed |

| Wheel caster resistance/ Pass EN 425 | Passed |

| Chemical resistance/ EN ISO 26987 | Passed |

| Smoke density/ EN ISO 9293/ EN ISO 11925 | Passed |