Product Description

Let's first understand the background of wood flooring and the prospect of wood plastics: as we all know, China is a country with a lack of wood resources. The forest coverage rate is 12.7%, and the forest volume per capita is 10 cubic meters, which is respectively 22% lower than the world average. Every year, 5-10 million cubic meters of wood are imported. The flooring used for home and office decoration is usually solid wood flooring or composite flooring and reinforced composite flooring Floor, need to consume a lot of wood.

Wood plastic material not only integrates the dual advantages of wood and plastic in performance, but also has significant characteristics of low carbon and environmental protection. Research data show that using 1 ton of wood plastic material is equivalent to reducing 1.82 tons of carbon dioxide, reducing 1 cubic meter of deforestation, saving 80 barrels of goods and 11 tons of standard coal.

The two environmental protection materials, stone plastic floor and wood plastic composite material, are the main materials "double sword wall", and its performance has made a qualitative leap. The new type of ecological floor of plastic wood lock will subvert the traditional concept of the existing floor industry and will lead the tide of the floor industry. The floor we produce is a better product instead of solid wood floor and composite floor. It overcomes the defects of solid wood floor and reinforced floor for fear of water and formaldehyde, and plays a good role in saving forest wood, reducing pollution and maintaining ecological balance fundamentally. It can be widely used in various commercial space, office space, health space, education space, entertainment space and home decoration, especially in kitchen, toilet and other places where water is afraid and easy to slide. Her appearance will resolve the current wood floor industry customers and businesses "difficult to buy, distribution difficult" dilemma.

Feature Details

Structural Profile

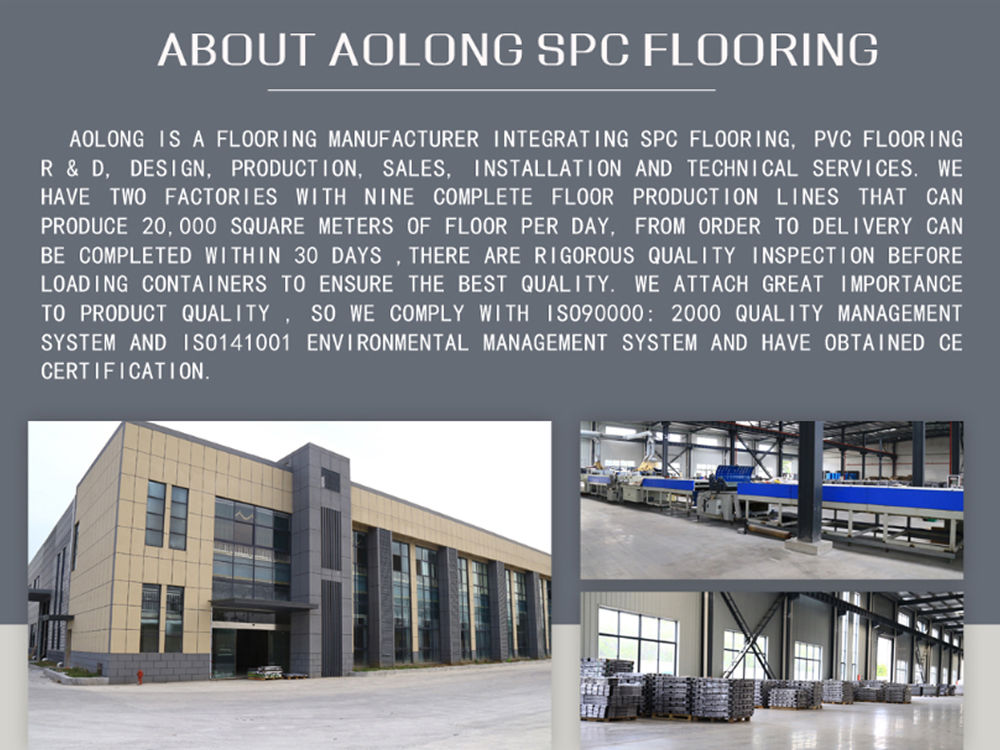

Company Profile

Test Report

Parameter Table

| Specification | |

| Surface Texture | Wood Texture |

| Overall Thickness | 12mm |

| Underlay(Optional) | EVA/IXPE(1.5mm/2mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Size specification | 1200 * 150 * 12mm |

| Technical data of spc flooring | |

| Dimentional stability/ EN ISO 23992 | Passed |

| Abrasion resistance/ EN 660-2 | Passed |

| Slip resistance/ DIN 51130 | Passed |

| Heat resistance/ EN 425 | Passed |

| Static load/ EN ISO 24343 | Passed |

| Wheel caster resistance/ Pass EN 425 | Passed |

| Chemical resistance/ EN ISO 26987 | Passed |

| Smoke density/ EN ISO 9293/ EN ISO 11925 | Passed |