Product Description

The stability and physical properties of CWPC products have been greatly improved by adding wood flour. Because of the existence of foam holes in the foam products, and the existence of wood flour plays a "link bracket" role between the foam holes, the structure of the foam products is more stable, the shrinkage is smaller, and the strength is higher.

The stability of CWPC products is better than that of common PVC / WPC foamed products. And the density is more uniform, and the shrinkage is very uniform (ordinary PVC / WPC foaming products usually have uneven shrinkage). Therefore, the stability of the finished floor produced by CWPC is better. It is worth mentioning that if CWPC products are used as the core of finished flooring, the cost is lower for flooring enterprises. CWPC not only has good physical properties and stability after heating, but also has a price advantage (cheaper than conventional PVC / WPC foam core), which can be said to be a real economic benefit, and also a good news for flooring manufacturers.

The market prospect of WPC floor is huge, but the domestic market has not been developed. Nowadays, under the severe attack of environmental protection, many small workshop style laminate flooring factories stop production, while WPC flooring production is simple, decorative layer and core layer can be purchased and processed into finished products, which is a good opportunity for laminate flooring factory transformation. WPC floor completely environmental protection characteristics, but also the gospel of the people. Its 100% recyclable features will become a major selling point in the secondary decoration market, the market potential is unlimited.

Feature Details

Structural Profile

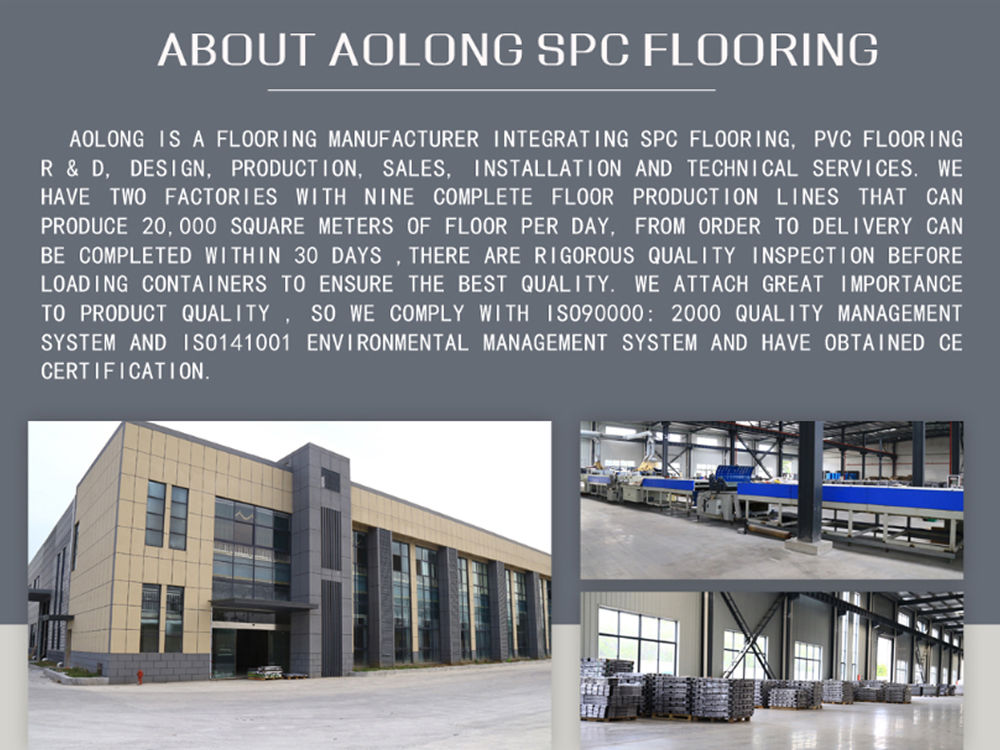

Company Profile

Test Report

Parameter Table

| Specification | |

| Surface Texture | Wood Texture |

| Overall Thickness | 12mm |

| Underlay(Optional) | EVA/IXPE(1.5mm/2mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Size specification | 1200 * 150 * 12mm |

| Technical data of spc flooring | |

| Dimentional stability/ EN ISO 23992 | Passed |

| Abrasion resistance/ EN 660-2 | Passed |

| Slip resistance/ DIN 51130 | Passed |

| Heat resistance/ EN 425 | Passed |

| Static load/ EN ISO 24343 | Passed |

| Wheel caster resistance/ Pass EN 425 | Passed |

| Chemical resistance/ EN ISO 26987 | Passed |

| Smoke density/ EN ISO 9293/ EN ISO 11925 | Passed |