Product Description

1. Wood plastic composite material has good processing performance, which contains plastic and fiber. Therefore, it has similar processing performance to wood. It can be sawed, nailed and planed. It can be completed by using woodworking tools, and the nail holding force is obviously better than other synthetic materials. The mechanical property is better than that of wood. The nail holding force is generally three times that of wood and five times that of particleboard.

2. For its material, then what is WPC floor, what can be reflected. The wood plastic composite has good strength property and contains plastic, so it has good elastic modulus. In addition, because it contains fiber and is fully mixed with plastic, its durability is obviously better than that of ordinary wood materials. The surface hardness is high, generally 2-5 times that of wood.

3. Compared with wood, wood plastic materials and their products are resistant to strong acid and alkali, water and corrosion, and do not breed bacteria, are not easy to be eaten by insects, and do not grow fungi. Long service life, up to 50 years. What is WPC floor? Generally speaking, it is wood plastic floor.

4, the excellent adjustable performance can be changed by polymerization, foaming, curing, modification and so on through the additives, so that the density and strength of wood plastic materials can be changed, and the special requirements such as anti-aging, antistatic and flame retarding can be achieved.

5. It has UV light stability and good colorability. After reading what is WPC floor, I believe you have understood. Let's take a look at the advantages of WPC floor.

Feature Details

Structural Profile

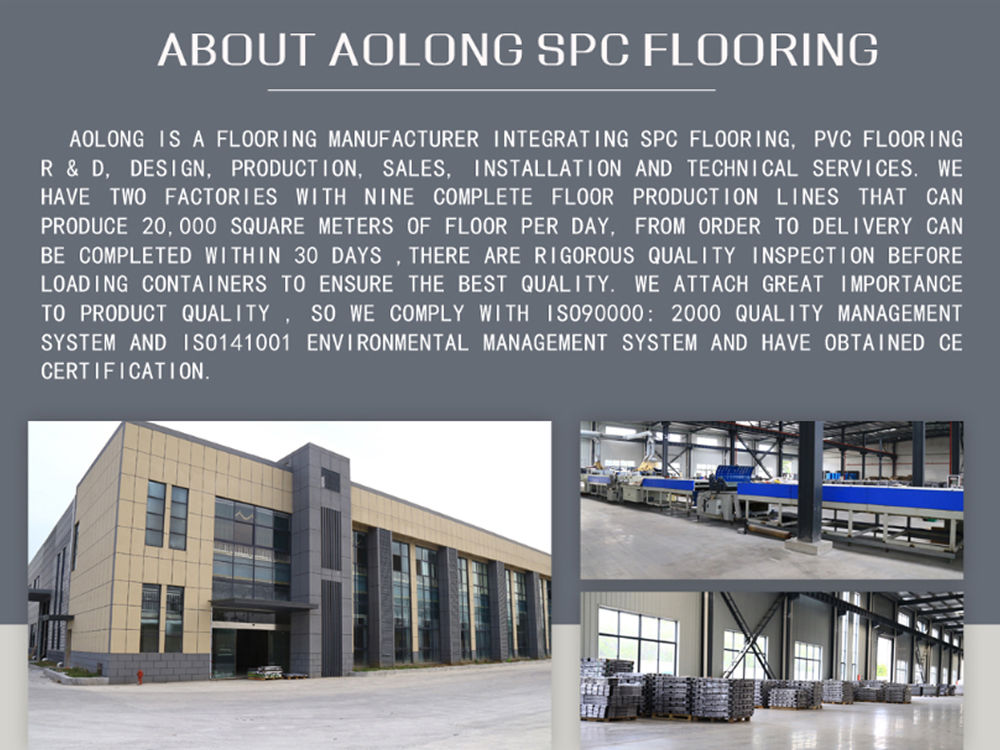

Company Profile

Test Report

Parameter Table

| Specification | |

| Surface Texture | Wood Texture |

| Overall Thickness | 12mm |

| Underlay(Optional) | EVA/IXPE(1.5mm/2mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Size specification | 1200 * 178 * 12mm(ABA) |

| Technical data of spc flooring | |

| Dimentional stability/ EN ISO 23992 | Passed |

| Abrasion resistance/ EN 660-2 | Passed |

| Slip resistance/ DIN 51130 | Passed |

| Heat resistance/ EN 425 | Passed |

| Static load/ EN ISO 24343 | Passed |

| Wheel caster resistance/ Pass EN 425 | Passed |

| Chemical resistance/ EN ISO 26987 | Passed |

| Smoke density/ EN ISO 9293/ EN ISO 11925 | Passed |