Product Description

How to choose a home floor

Water absorption thin thickness expansion rate: the water absorption thin thickness expansion rate of superior products is below 2.5%; The water absorption thin thickness expansion rate of the first class product is below 4.5%. Tap water foam has many poor qualities of absorbing water.

Surface wear resistance: the floor is called false floor because it has no wear-resistant layer or very low number of wear-resistant turns. There is no difference between the surface of such floor and the real composite floor. After polishing with sandpaper for many times, it will be found that the decorative pattern is polished and immediately white. This kind of floor is false floor. If your family population is large, do not pay attention to maintenance, can choose wear-resistant performance higher; But if you pay more attention to the maintenance of the floor, the floor is less opportunity to be damaged by strength and hardware configuration, it is likely to be more economical and affordable to choose a lower relative wear resistance. Wear resistant at home in 6000 RPM can be.. Can use sandpaper to wipe, the quality is very easy to detect. The key to the wear-resistant compressive strength of composite floor is the coating of aluminum trio3 crystal (also known as crystal). The higher the total area of the floor, the higher the content of the aluminum oxide crystal, the higher the wear resistance.

Feature Details

Structural Profile

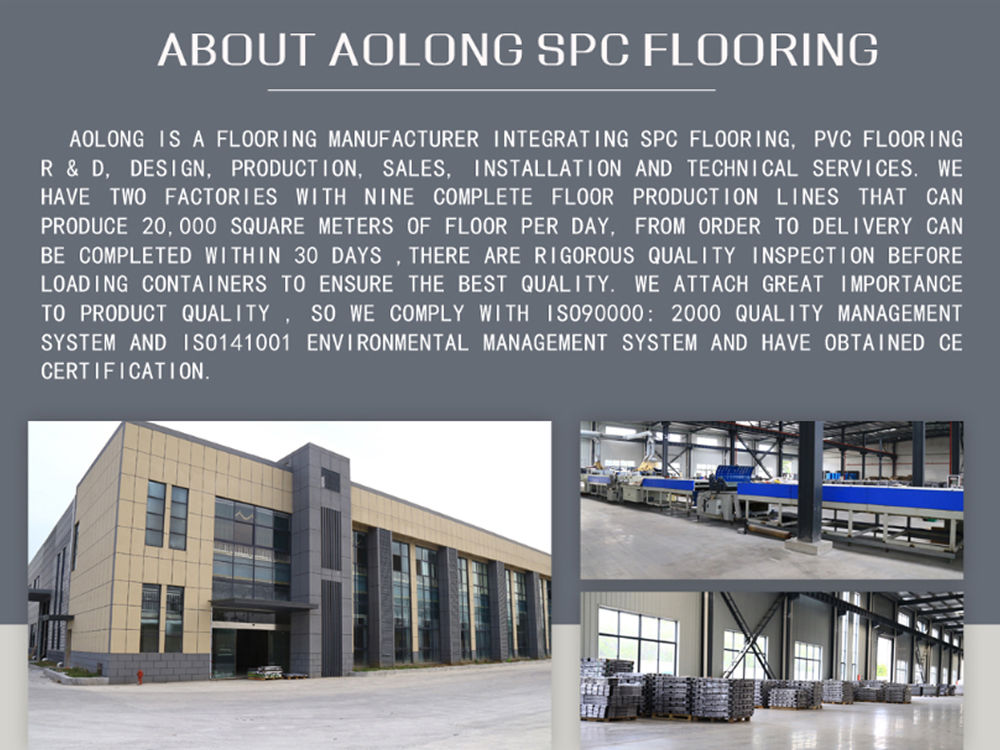

Company Profile

Test Report

Parameter Table

| Specification | |

| Surface Texture | Wood Texture |

| Overall Thickness | 4.5mm |

| Underlay(Optional) | EVA/IXPE(1.5mm/2mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Size specification | 1210 * 183 * 4.5mm |

| Technical data of spc flooring | |

| Dimentional stability/ EN ISO 23992 | Passed |

| Abrasion resistance/ EN 660-2 | Passed |

| Slip resistance/ DIN 51130 | Passed |

| Heat resistance/ EN 425 | Passed |

| Static load/ EN ISO 24343 | Passed |

| Wheel caster resistance/ Pass EN 425 | Passed |

| Chemical resistance/ EN ISO 26987 | Passed |

| Smoke density/ EN ISO 9293/ EN ISO 11925 | Passed |